A Technician Performance Report provides crucial information to achieve workshop efficiency and should be monitored frequently:

- Efficiency: This indicator reveals the dealership’s cost per hour billed to customers.

- Productivity: This indicator shows how each technician’s time is used to perform repairs. Available hours are considered, deducting time dedicated to tasks unrelated to repairs (e.g. workshop cleaning).

- Performance: Measures how many available hours were billed.

Measuring and interpreting these indicators is vital, but it is also important to know what can be done to improve them… and then to do just that. Autologica offers tools designed to maximize profitability in the workshop, enabling more effective management and informed decision-making.

How to Improve?

There are several recommended strategies to address common concerns such as quickly seeing pending jobs, detecting delays in a timely manner, and addressing idle time in the workshop.

Monitor Pending Jobs

The workshop manager must take advantage of the early morning hours to organize jobs, and that isn’t possible if they waste time accessing and cross-referencing information, consulting spreadsheets, or asking around. For technicians to be efficient, workshop management must be as well.

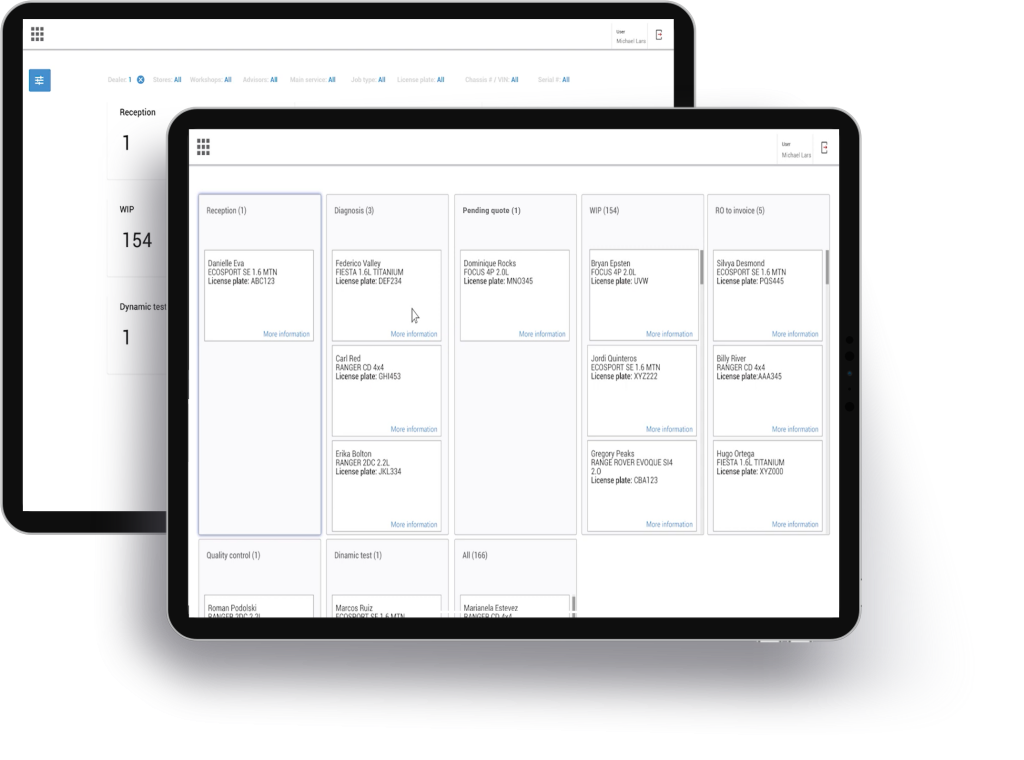

With tools like Repair Order Progress, you can have a real-time overview of all open jobs and their status, and can thus detect bottlenecks and jobs that remain open for too long, and can understand each operator’s workload.

“RO Progress has become the ABC of good workshop planning… I open the application and can instantly see where we stand. This saves me at least one hour every day.”

UB Motors – Official Audi Dealership

Detecting Delays in Time, and Then Taking Action

Can lack of communication affect efficiency and productivity? Of course, especially when there are no clear and immediate channels to request assistance and resolve delays, order parts and accessories, etc.

Autologica’s Tecnicinan Panel lets the workshop manager see the real-time status of each job, detect delays, and understand the root causes to act quickly. The inclusion of this technology in the workshop is a minor investment compared to the advantages it brings.

Accurate Recording of Each Hour Used in the Workshop

The right tool provides a detailed approach to measure work hours accurately and in real-time. The Job Clock overcomes common challenges in time management, significantly improving workshop efficiency and productivity. This solution not only optimizes daily operations but also contributes to transforming the service area into a profit engine for the dealership.

Habits that Generate Daily Improvements

Improve processes: To reduce delays and unproductivity, it is necessary to identify the root causes and then correct and modify work processes.

Training technicians: Trained employees reduce the time they work on each unit.

Incentives: A reward plan for technicians who meet their time objectives encourages more efficient work with a minimal monetary impact.

Measuriung KPIs must go hand in hand with the decision to take action. The right tools facilitate decision-making, without depending a manager’s intuition. Autologica Sky DMS improves workshop operations based on reliable, immediate data and is designed to drive substantial change in the dealership.