Global trends, added to the local and regional panorama, will require focusing on after-sales to make dealerships more profitable, but also to offer a unique experience to customers.

An Innovative Proposal

Taking this scenario into account, auto and equipment dealers can work on different multiple fronts to leverage every hour in the workshop, offer unique experiences to customers, promote efficient processes, and eliminate delays.

To have an efficient service department, a series of issues must be solved:

- The workshop must function smoothly and in synergy with other areas.

- The workshop manager must have a 360 degree view of everything that happens in the department.

- Technicians must have tools that help streamline their tasks.

- The Service Manager must have reports to make strategic decisions.

It is within this framework that we propose a series of tools integrated into Autologica Sky DMS that help achieve this differentiating service that enhances the customer experience.

What Tools Are Important for This Transformation?

Our workshop strategy must allow us to have a 360° view of what is happening in the Service Department.

How Much Work Is Done on Each OR?

In dealerships with many work bays, it becomes necessary to know how each and every hour is used. For this there is a tool called Job Clock that allows each technician to set the start and end time of each job, and that also indicates delays.

For example, if an operator must stop working due to a lack of parts, they can mark it and the Service Manager will see this live on a Technician Panel. The manager can then act instantly. The Job Clock also helps anticipate idle hours due to lack of jobs, detect jobs that are taking longer than normal, etc.

First achievement: a more efficient workshop, and a customer who receives their vehicle sooner.

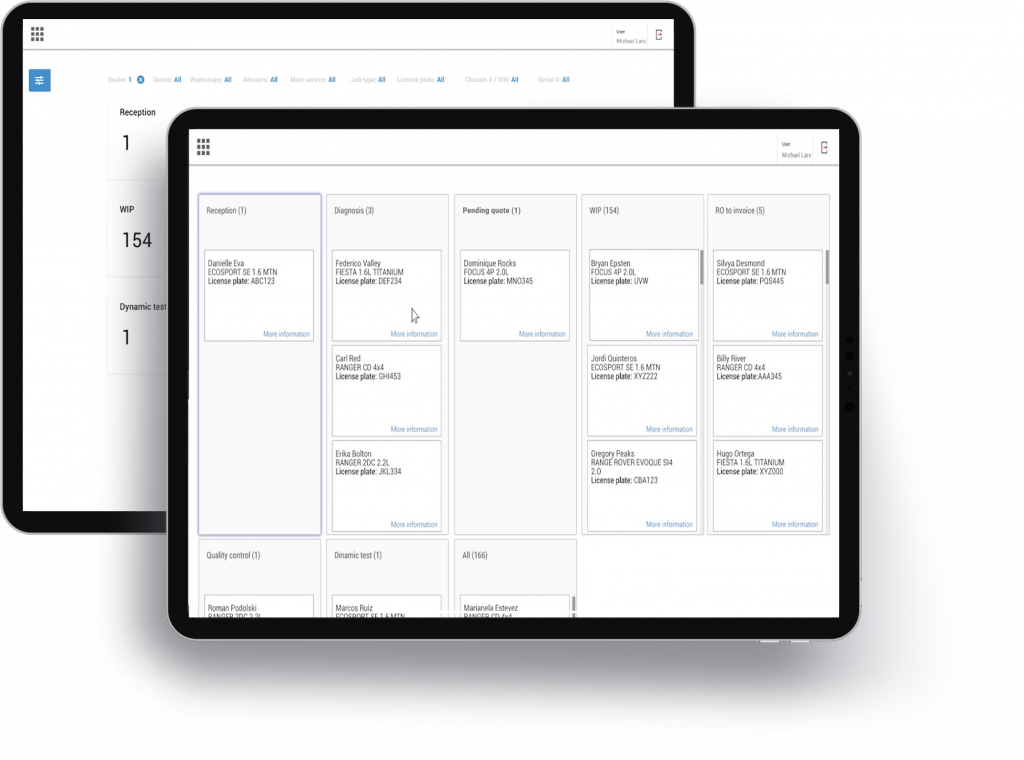

Where Is Each Vehicle?

The Repair Order is the main protagonist in the Autologica Sky DMS service module. This document records each job (performed by our own staff or by thirp parties) and each part involved in a service. From the moment the order is generated to its invoicing, there are several stages: reception, proposal, ordering parts, work on the vehicle, quality control, etc.

Knowing what stage each unit is in allows us to detect delays, make decisions and keep the customer informed of the progress of the repair of their vehicle. This used to be done with unit identification cones, to physically see where each vehicle was. This can now be automated and digitized using Autologica’s Repair Order Stages tool.

As steps are completed in the DMS, the Repair Order will progress on a dashboard that the Service Manager can monitor at all times.

Know the Results of the Department

These tools help management visualize what is happening in the workshop in real time, but the department’s results are vital for making decisions.

For that we’ve developed an app called KPI Dashboard, a mobile and web application for managers and principals who want to know the most important sales indicators of each department: new and used vehicles, parts and services.

The KPI Dashboard allows you to apply filters by dealer, branch, and warehouse, and is 100% integrated with the Autologica Sky DMS database. In this way, with a few taps, at any time and place managers can see the composition of service sales segmented by sales type (warranty, customer, internal). This helps management see how much the workshop sells, and detect peaks, drops, and trends.

These three tools work together to achieve a fully integrated Service Department, flexible and ready to face a scenario where after-sales are key to positive business results.